Oil Purification Plant/Cooking Oil Cleaning Machine/Used Cooking Oil Purifier Cop

Introduction: COP is for filtering waste cooking oil, dirty vegetable oil, trench oil, swill oil, animal oil etc. It eff;

Basic Info

| Model NO. | COP |

| Certification | ISO9001, CE |

| Application | Cooking Oil |

| Voltage | 380V,50Hz, 3 Phase (or as Needed) |

| Folw Rate | 600-18000L/H |

| Structure | Mobile |

| Mechanical Principle | Vacuum |

| Type | Suction Filter |

| Pressure | 0.4MPa |

| Condition | New |

| Color | as Needed |

| Total Power | 38-147kw |

| Transport Package | Standard Export Wooden Case |

| Specification | ISO/CE |

| Trademark | TOP Oil Purifier |

| Origin | Chongqing, China |

| HS Code | 84212990 |

| Production Capacity | 100 Sets Per/Mouth |

Product Description

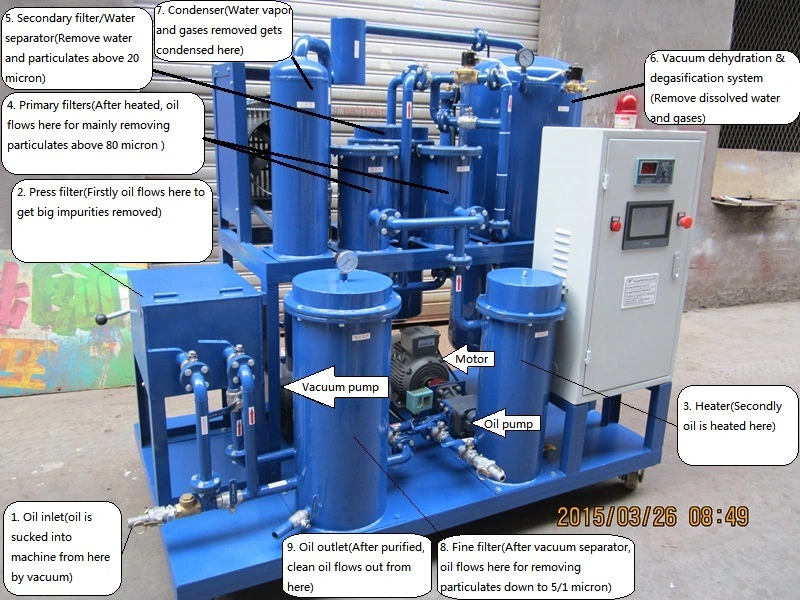

Introduction:COP is for filtering waste cooking oil, dirty vegetable oil, trench oil, swill oil, animal oil etc. It effectively and completely removes particles, odor, water, acid, alcohol etc. from the waste oil. The treated oil is clean, limpidity, and with good smell. COP is an ideal purification machine for bio-diesel factory, fried food factory, oil restaurant, cooking oil factory, vegetable oil factory, waste oil collecting store etc. For edible usage of treated oil, we can make COP of stainless steel.

Features:

1.This plant is mainly composed of two parts:press filter and vacuum oil purifier system. The press filter removes the big or tiny impurities; The precision reaches to 1 Micro. The vacuum system is equipped with filters of three grade (primary filter, mass water separator, and fine filer).

2. The primary filter of stainless steel is anti-rust and anti-corrupt. It mainly removes the residual impurities which escape from the press filter, making sure the treated oil won't have any impurity when it goes into the water separator and vacuum separator.

3. The water separator mainly removes mass water from oil. After the water separator, the oil just contains the tiny water and soluble water.

4. After water separator, oil goes into the vacuum separator which adopts three-dimensional duplex evaporation and film evaporation. The tiny water, soluble water, acid, alcohol, other volatility liquid and so on can be removed completely and effectively.

5.For stainless steel fine filter, the purification hole is less than 1 Micro, which can make sure the filtered oil is completely clear.

Technical Parameters:

| Parameters | Unit | COP-10 | COP-20 | COP-30 | COP-50 | COP-100 | COP-150 | COP-200 | COP-300 | ||

| Flow Rate | L/min | 10 | 20 | 30 | 50 | 100 | 150 | 200 | 300 | ||

| Working Vacuum | MPa | -0.06 ~ -0.095 | |||||||||

| Working Pressure | MPa | ≤0.4 | |||||||||

| Temperature Range | ºC | 0 ~ 100 | |||||||||

| Power supply | 380V,50Hz, 3 phase (or as customized) | ||||||||||

| Working noise | dB(A) | ≤75 | ≤75 | ≤75 | ≤78 | ≤78 | ≤78 | ≤80 | ≤82 | ||

| Heating power | KW | 36 | 40 | 45 | 72 | 80 | 90 | 120 | 135 | ||

| Total power | KW | 38 | 42 | 47 | 75 | 87 | 101 | 135 | 147 | ||

| Inlet/outlet | mm | 25 | 25 | 25 | 32 | 42 | 50 | 50 | 60 | ||

| Net weight | Kg | 450 | 550 | 600 | 750 | 850 | 1000 | 1200 | 1500 | ||

| Overall dimensions | mm | 1500×1000×1200 | 1500×1050×1600 | 1500×1050×1650 | 1600×1150×1700 | 1750×1250×1800 | 1900×1600×1950 | 1900×1700×2000 | 2100×1700×2100 | ||

Guarantee Value:

| Item | Guarantee indexes |

| Moisture content | ≤50 PPM |

| Demulsification value | New oil≤15min,running oil≤30min |

| Impurity size | ≤1 micron (no free carbon) |

| Gas content | ≤0.1% |

| Clean degree | ≤4 Grade (NAS1638) |

Our Service

Pre -sale Service:

1. Reply promptly in 24 hours with fluent English and professional knowledge

2. Provide best necessary spare parts at low price (some for free)

3. If there is something wrong with the equipment,we will give a response and provide the solutions in 24h

4. Provide long term technical support and innovation upgrade guidance

5. OEM is available for TOP Products

6. Protect sales area, ideas of design and all your private information

After-sale Service:

1.The warranty period is 24 months from commissioning acceptance date on. After the warranty period is over we provide lifelong maintenance and technical service.

2. We guarantee the maintenance time no more than 3 working days and response time within 1 hour.

3. We build instrument service profile for our clients to record the product service and maintenance conditions.

4. After instruments start service, we will pay follow-ups to collect the service conditions.

Our Company:

Chongqing TOP Oil Purifier Manufacture is a professional leading manufacturer of oil purifiers and oil testers. We have tremendous strength in the fields of research, development and manufacturing with professional mass-production ability, perfect sales network, excellent after-sales service as well as a perfect image we earned in the competitive market.

Our main products are: Insulting Oil Purifier, Turbine Oil Purification machine, Hydraulic Oil Purifier, Lubricating oil filtration machine, Transformer Oil filtering machine, fuel oil restoration, Steam-Turbine Oil reconditioner, Dielectric fluid regeneration system, Circuit-Breaker Oil recovering system, Compressor Oil recovering machine, Gear Oil renewal machine, Coolant Oil treatment, Quenching Oil reclaiming machine, Oil and Water Separator, Steel-Rolling Oil regeneration equipment, Waste automobile Oil Recycling equipment, petroleum machine and Oil Tester, etc.

Our oil filtration machine:

Series ZY Single-Stage Vacuum Transformer Oil Purifier

Series ZYD Double High Vacuum Transformer Oil Purifier

Series ZYB Multiply-Function insulating oil treatment machine

Series TY Turbine Oil Purification Apparatus

Series TYA Lubricating oil/ hydraulic oil purification unit

Series TYB Portable light Fuel oil purification machine

Series TYD Vacuum dehydrator

Series TYF Phosphate ester fire-resistance oil purifier

Series PL Plate pressure oil purifier

Series TYD Vacuum dehydrator

Series EFD Explosion protection filtration machine

Series BAM Press filtration system

Series ZKCC Vacuum pumping device

Series COP Cooking oil purification machine

Series CYS Centrifugal oil purification machine

Series JL Portable oil filtering and oiling machine

Petroleum Products General Testers:

1.Fully Automatic Karl Fischer Water Content Tester TP-2100

2.Digital Karl Fischer Water Content Tester TP-6A

3.Kinematic Viscosity Tester VST-2000

4.Kinematic Viscosity Tester TPV-8

5.Kinematic Viscosity Tester VST-3000

6.Fully Automatic Oil Acidity Tester (6 cups) ACD-3000I

7.Fully Automatic Surface/Interface Tension Tester IT-800

8.Automatic Surface/Interface Tension Tester (Platinum Plate Method) IT-800P

9.Fully Automatic Open Cup Flash Point Tester TPO-3000

10.Fully Automatic Closed Cup Flash Point Tester TPC-3000

11.Digital Open Cup Flash Point Tester TPO-100

12.Digital Closed Cup Flash Point Tester TPC-100

13.Cloud Point & Pour Point Tester PT-2000

14.Multi-functional Vibration Tester VBT-2000

15.Automatic Potentiometric Titrator TP668

16.Petroleum Products Density Tester DST-3000

17.Petroleum Products Density Tester TP-109A

18.Karl Fischer Volumetric Water Content Titrator TPD

19.Distillation Range Tester DIL-201

20.Online Oil Quality Tester PTT-002

21.Liquid Phase Corrosion Tester TPS-05

22.Copper Corrosion Tester TP-113

23.Petroleum And Synthetic Liquid Anti-Emulsification Tester TP-122

24.Dew Point Tester DPME-P

25.Portable Chilled Mirror Dew Point Tester TP-1500

Welcome to contact us freely for more details

Have a nice day!

You may also like

Send inquiry

Send now